To make powerful hydraulic yews for a garage or your own home workshop with your own hands, you will need hydraulics, which are used in the process of bodywork.

Unlike ordinary mechanical vice, which are designed for locksmith work, homemade hydraulic yews have a higher clamping force of parts and workpieces. Moreover, they can be made independently using available materials.

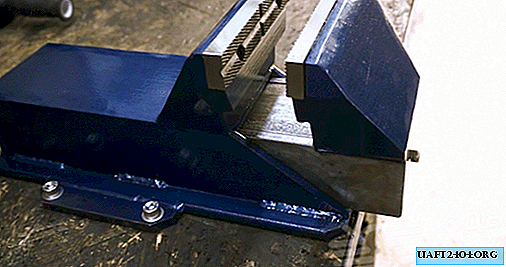

First of all, from a piece of sheet metal with a thickness of 1.5-2 cm using a grinder or a plasma cutter, it will be necessary to cut a rectangular plate and two narrow stripes. Then we weld all three workpieces together. In narrow plates, two through holes must be drilled.

The main stages of work

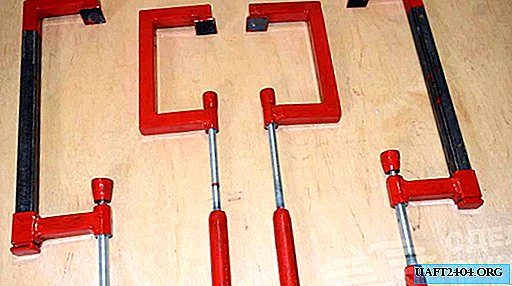

We cut the size of two steel plates with a thickness of 1.5-2 cm, and drill through holes in them (four holes per plate). Then cut off a suitable piece of channel length. After that, we fix the workpieces with clamps and weld together.

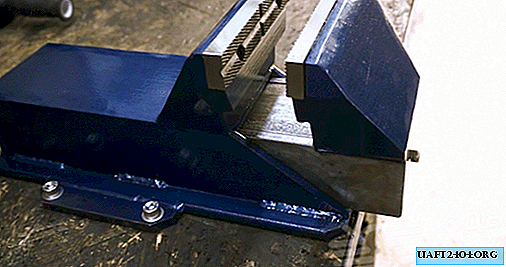

The next step will require three metal plates, two of which will need to be cut at an angle (they will be used as side walls). We weld them to the base of yews.

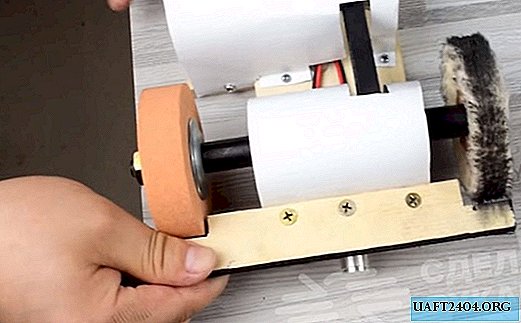

After the yew box itself is made, we install the hydraulics directly, and for convenience we make a foot drive. Then we make and fix the clamping jaws in their place.

For details on how to make powerful hydraulic yews for the home workshop, see the video on our website.