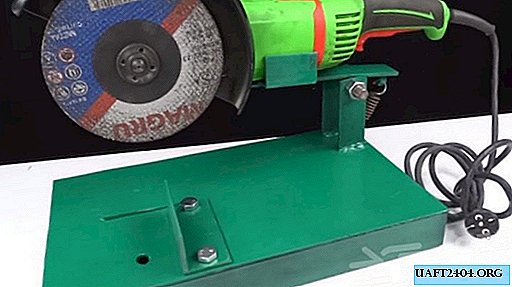

Using this device, you can make working with an angle grinder as comfortable, convenient and most importantly safe. You can make a working platform-stand from improvised materials that are in any workshop or garage.

Manufacturing process

For the base, you can use a steel sheet 44 cm long and approximately 25-30 cm wide. You will also need to prepare two metal corners along the length of the sheet and weld them along the edges of the base. Another equal-angle corner with a length of 25-30 cm (depending on the width of the sheet) needs to be welded to one of the perpendicular sides of the future platform.

Additionally, a steel plate with a width of 4 cm and a length of 38-40 cm is required, in which one through hole must be drilled at a distance of about 2-3 cm from the edge. Then this plate must be connected to the housing of the grinder with a bolt. For greater strength, you need to use two more small pieces of steel corner, which then need to be welded to the plate.

Assembling the design

Also, for this design, it will be necessary to use two pieces of a steel plate 11 cm long, in which it is necessary to drill holes, and a piece of a hollow pipe - all parts must be joined together using a bolt and nut. The resulting rack must be welded to the base of the working platform, and then a plate with corners, which is directly attached to the grinder, should be welded to it.

Then it remains only to make the right-sized stop from a steel corner and also connect it to the platform. That's all - a practical and convenient working "table" for the grinder is ready. With such a useful device, you can perform various technological operations much better and faster. The detailed process of manufacturing the platform, see the video on our website.