If we talk about which hunting knives are better (store or homemade), then there is no consensus. However, today hand-forged products are on a special account - they are not only beautiful in appearance, but also differ in excellent quality.

Homemade blades are noteworthy in that they can be made from a variety of materials that are at hand. If you are looking for new ideas for creating unusual knives, use a blacksmith or carpentry chisel as a blank.

In most cases, in the process of manufacturing a carpentry bit, high-quality tool steel of the U7 grade is used, and the tool itself has a hardness of Rc = at least 50. Therefore, home-made knives from the bit are obtained in a fairly decent quality. Well, of course, a lot depends on the blacksmith himself.

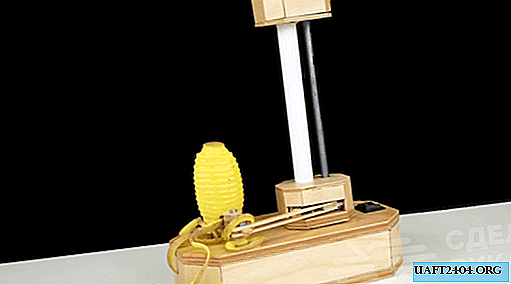

Manufacturing process

First of all, we preheat the billet red-hot in the furnace, after which we begin to rhythmically “beat off” the sledgehammer. It is necessary to flatten the bit on the anvil until a rectangular plate of suitable thickness and length is obtained.

Then from the resulting workpiece we form the nose (tip) and the tail of the knife. The main emphasis will be on the handle, so we process the shank on the milling machine, then we need to work a bit with the grinder and in the end we finish the handle on the belt grinder.

After machining, we again heat the handle red-hot, hold it in a vise and twist it counterclockwise with a gas pipe wrench. Well, then we process the blade itself. You watch the main stages of manual forging of a knife from a chisel in the video on our website.