To make a home-made grinding machine for a home workshop with an eccentric mechanism, you will need a minimum of materials that will always be found under your feet (sawn timber).

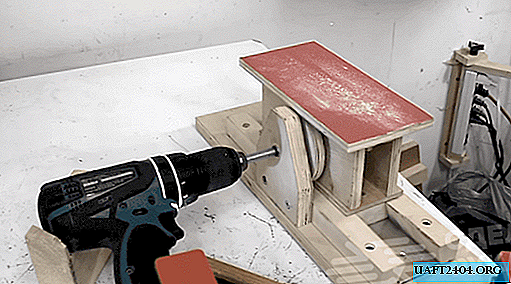

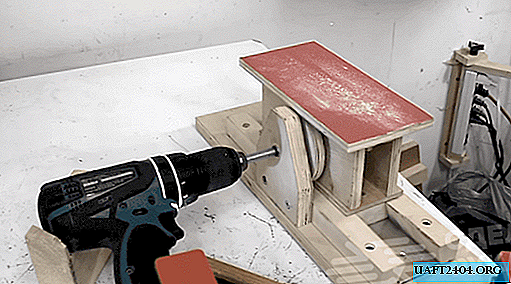

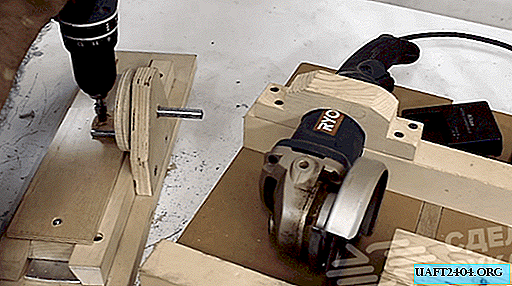

The body of the grinding machine is made entirely of pieces of plywood (you can also use wooden planks). The main structural elements are interconnected by self-tapping screws. A screwdriver is used as an electric drive for this grinding machine.

As you can see, all materials are very simple and affordable, and finding them will not be difficult. If you are interested in how to make a grinding machine with an eccentric mechanism, read the article further.

The main stages of work

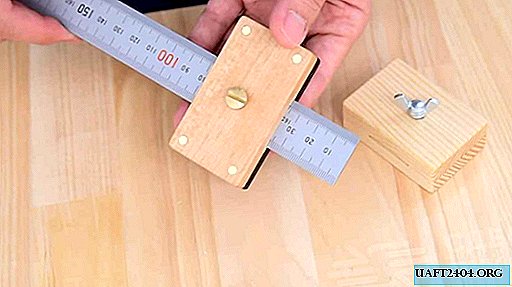

First of all, from the plywood sheet we cut out the base for the rectangular machine. Dimensions are selected individually, depending on the availability of free space on the desktop or your needs.

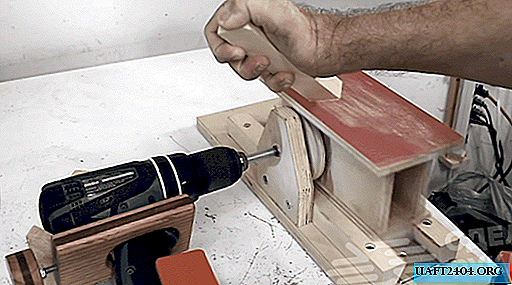

After that, on a circular saw, cut two plywood blocks at an angle of 20 °. The result should be guides for the movable carriage. The carriage of a self-made grinding machine itself is also made of plywood and cut at an angle of 20 degrees.

To slide the carriage freely along the surface of the base, we lay an aluminum strip of suitable width under it. Then we fasten the guides to the base using self-tapping screws, and proceed to the manufacture of the eccentric mechanism. Next, we collect all the structural elements together.

For a detailed process of manufacturing a homemade grinding machine with an eccentric mechanism, see the video on the site.