Share

Pin

Tweet

Send

Share

Send

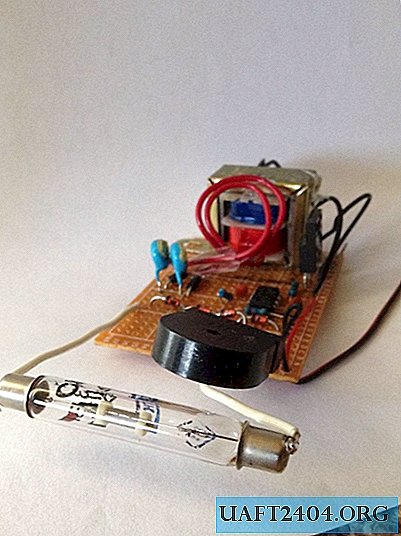

Hydrogen when mixed with air forms an explosive mixture - the so-called explosive gas. The combustion temperature of hydrogen is 2800 degrees. Celsius. It is on these facts that this gas welding is collected. The basis of welding is an electrolyzer, which is charged with a solution of alkali in water, i.e. ordinary soda (sodium bicarbonate) and generates Oxygen, and Hydrogen is a mixture that burns perfectly. This is how the finished unit might look:

So, let's start with the assembly of the cell itself. We will need:

1. Sheet stainless steel (stainless steel)

2. Rubber or plastic

3. Plexiglas or as it is also called fiberglass

4. Bolts with nuts

5.Sealer

6. Connecting nipples and branch pipes

Let's get started. To start, we cut stainless steel plates

After this, it is necessary to drill holes in the plates for the circulation of the solution and the passage of gas between the compartments

Now we cut the insulating plastic gaps, it is better to make them from rubber, but I did not find it and I used plastic and silicone sealant

It turned out not very elegant, the main thing is workable.

It remains to cut the lateral bases from plexiglass and you can start assembling. In order to match the bolt holes, I recommend putting one glass on top of another and carefully drilling two holes diagonally and securing them with screws, so the glasses will not move out when drilling

Now you can start the assembly.

Start on plexiglass, we smear the sealant and lay the plastic on the plastic with a stainless steel bed and so on, smearing everything with sealants as a result, we get such compartments for the solution

The most extreme plates need to be taken away so that contacts can be fixed.

Because of, to put it mildly, errors in the calculations, two bolts were not included.

Before closing the upper compartment in the glass, two holes must be made at the top for the gas to escape and the bottom to maintain the solution level

The lower nozzle must be connected to the bottle into which the solution will be poured and, according to the principle of communicating vessels, the solution will enter the compartments

Then you need to make a water shutter. Since explosive gas escapes from the electrolyzer, a flame can easily go through the tube and explode, this happens in just a split second. Thus, I lost three 0.5 bottles each. And so in a cork two holes are made into one, the electrolyzer tube enters and is immersed in water. The burner tube is inserted into the second hole.

As a burner, a regular syringe is used, namely a needle

A very powerful source of direct current is used for power supply, a voltage calculation of 2 volts per stainless steel plate, a current of at least 7 A. Current is supplied to the end plates.

Now the simplest solution is to prepare the solution. Ordinary soda is added to the water. Ideally, it is better to take NaOH (caustic sodium, caustic soda) but it is not so easy to find, the concentration of soda is calculated by amperage. The current should be in the range of 4 to 6 amperes (for ordinary soda).

Before assembling the unit, remember that hydrogen is extremely explosive enough small sparks to cause an explosion. The combustion temperature of hydrogen is high and therefore the non-combustible gases that make up the air expand very much and a very strong cotton occurs, for this reason I was jammed on both ears twice and tore out the bottom of three bottles.

That's all you can use.

This is what happened with a conventional capacitor. It is better to extinguish the burner by lowering it into water, and not by turning off the power in this case, an explosion occurs.

I repeat that the combustion temperature of hydrogen is about 2800 degrees Celsius, therefore it is possible to melt all metals whose melting point is lower, namely:

Lithium

Potassium

Sodium

Calcium

Magnesium

Cesium

Aluminum

Barium

Zinc

Chromium

Manganese

Tin

Iron

Cadmium

Nickel

Copper

Bismuth

Silver

Lead

Tungsten

Gold

Platinum

Osmium

Wishing to repeat good luck!

Video with a clear explanation:

Share

Pin

Tweet

Send

Share

Send