Share

Pin

Tweet

Send

Share

Send

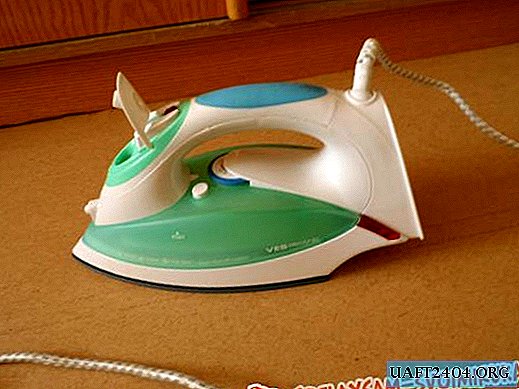

Consider the disassembly sequence of a modern iron using the VES 1616 model as an example. The iron should be cold and without water.

At the end of the iron there is a “tricky” screw, which requires a flat screwdriver with a slot in the middle to unscrew. Such a slot can be made in a conventional screwdriver with a file or a grinder.

The following screws are hidden under the water buttons. Buttons can be easily removed by pushing them in the front. The back of the button rises and can be pulled out of their iron body.

Now you need to unscrew the upper two screws and remove the upper element.

Next, unscrew 3 more screws and dismantle the lever that regulates the water supply.

Now remove the back cover, where the "tricky" screw is already turned out, and unscrew the 2 screws in the upper part of the iron.

Pry off the upper part of the handle with a screwdriver, half it.

Next, pry up the heating controller and dismantle the controller and the bottom of the handle.

Now you can see 3 screws that secure the “aquacorpus" to the platform. We twist them, disconnect the tube through which water is supplied to the “sole” and remove the housing for water content.

It remains to unscrew another 3 screws and perform the last dismantling of the element.

Now, using a vacuum cleaner with a narrow nozzle, we clear everything from the accumulated dust.

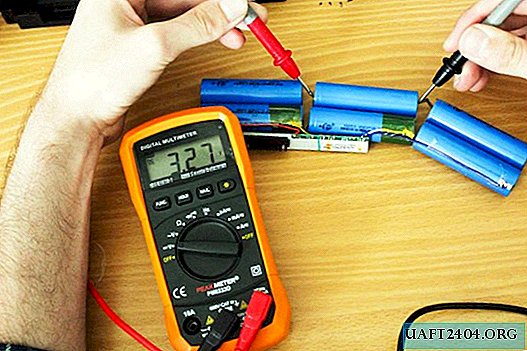

After this, some iron malfunctions are eliminated. And then, armed with a tester, you can “ring” the heating element, wiring, conduct a visual inspection, etc.

All fasteners and small iron parts are conveniently put in a box.

The iron is assembled slowly in the reverse order.

Share

Pin

Tweet

Send

Share

Send