During carpentry and locksmithing operations in a workshop or garage, clamps are indispensable - they can be used to glue wooden products and securely fix metal workpieces to the surface of the workbench, which simplifies the work process.

But store clamps rarely come across good quality, so it’s better not to spend money on Chinese consumer goods, but to make a home-made clip in the form of the letter “G” is one of the most common configurations.

As the main material, we will use profile pipes (you can even take the scraps that remained from previous homemade products). To work, you will need a grinder or a band saw with a metal blade, as well as a welding machine.

The manufacturing process of the G-shaped clamp

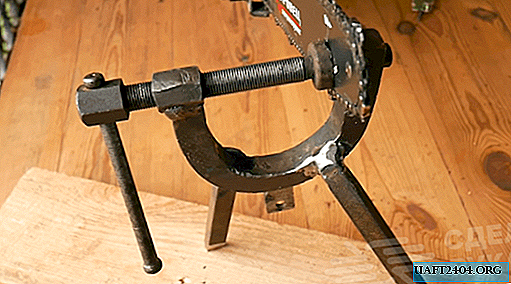

Five sections must be cut off from a profile pipe with sides 30x30 mm (other sizes can be used) at an angle of about 60 degrees. Then we clean the places of cut and weld from them a G-shaped part - the basis of the clamp.

An elongated M12 nut must be welded to the bottom of the tube frame, into which the stud will be screwed. A steel nickel is welded to the upper edge of the stud (can be turned on a lathe), and to the lower nut, in which a hole is drilled and a thread is cut inside.

We screw a bolt or a piece of rod into the resulting hole, on which we also need to cut the external thread. A piece of a rectangular plate is welded to the top of the clamp - this will be the clamping sponge. Then it remains only to paint the frame and the home-made clamp is ready for use. Very simple and budget option.