Unlike a traditional carpentry or construction ax, the cleaver has a more obtuse angle of convergence of the edges, due to which, when struck, it pushes the wood fibers to the sides, breaking the log into several parts without problems.

In this regard, such a tool is especially convenient for chopping large logs, which are more difficult for an ordinary ax to handle. Why harder? Because its sharper sharpened blade will constantly get stuck between the fibers. The cleaver is devoid of such a drawback and it is much easier to work with it.

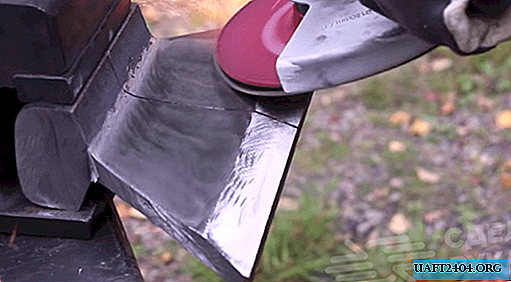

A powerful splitting ax for splitting large logs can be made with your own hands from a piece of a railway rail. To implement this idea, you will need to stock up on a large number of cutting wheels for the grinder and patience - the process of processing the rail will take a lot of time.

The main stages of work

The first step is to cut off the side parts of the sole of the rails flush with the neck. Then we make the markup and cut out the main part of the cleaver. For reliable fixation of the workpiece, a powerful vice with a vertical clamp or a homemade device will be required.

At the next stage of work, we form the slopes of the blade using a small angle grinder with a flap wheel. In the back of the workpiece, cut a triangular wedge. The resulting "groove" is treated with a file for metal, giving it a U-shape.

Then we give the cleaver the final shape, polish it and cut it into two parts. The resulting halves are welded together.

Then it remains only to cultivate the whole thing with the help of angle grinders, and also to make a wooden hatchet.

For a detailed process of making a powerful hand cleaver from a piece of rail, see this video.