G-clamps are often used to fix metal or wood workpieces. They are very convenient and easy to use. However, they cannot be used to “immobilize” the workpiece or part in the middle of the table. However, this shortcoming can be corrected.

A simple but useful refinement of a conventional G-shaped clamp will make it possible to use the clamp both "near and long distance". The result is a versatile tool that will definitely come in handy in the workshop.

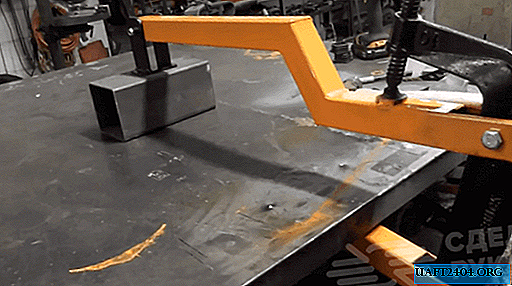

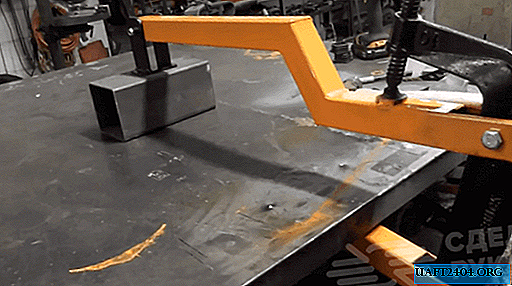

To refine the G-shaped clamp, profile square tubes will be needed (size - at your discretion). First we mark and drill holes. And then we cut out a part of the wall with a grinder.

Step-by-step master class

We make markings on the frame of the clamp and drill two through holes. Then it will be necessary to cut four more workpieces from a profile pipe of the same cross section - two long and two shorties. We weld the parts together so that in the end we get two shoulders.

Next, cut out six plates of the same size. We fasten two plates on the sides at the free end of each shoulder, and weld the remaining two on the bottom. In this case, they will act as clamping jaws.

At the last stage of the work, it remains only to paint the composite parts and screw them to the frame of the G-shaped clamp. The finalization process can be seen in the video on the site. Do you like this advanced joinery clamp? Write about this in the comments.