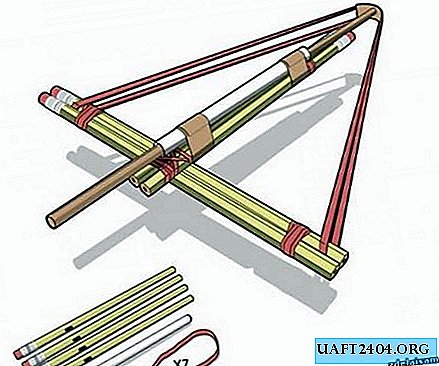

When welding ordinary round or square shaped pipes, it is often necessary to fix the workpieces using improvised tools. The fact is that standard bench vices are not always able to cope with this task properly.

To make a universal clamp for fixing round or square pipes, you will need: five pieces of a metal strip, two pieces of a corner, a long pin, bolts with nuts, a washer and a profile pipe.

First of all, it is necessary to cut off five metal strips of the same length from a metal strip. They need to mark and drill holes.

Step-by-step universal clamp manufacturing process

In the next step, you will need to fold four plates in pairs and cut a triangular slot into them so that you can weld pieces of the corner.

After that, the master cuts off a piece of the stud and welds it to the nut, which is screwed onto the bolt. The corner pieces must be inserted into the slots in the plates, and scald.

Next, you need to weld a piece of the profile pipe to one of the parts, after which it will be necessary to strip the welds with a grinder, and you can proceed with the assembly of the homemade device.

For details on how to make a universal clamp for fixing round and square pipes with your own hands, see the video on the website.