Share

Pin

Tweet

Send

Share

Send

I saw a lot of different technologies and methods for manufacturing solar water heaters on the Internet and decided to share my own experience. I think this project is very successful, since literally every centimeter of the collector surface is in direct contact with heated water. In addition, taking the technology as a basis, you can easily build a collector of the right size.

Project concept

The essence of the solar collector is that cold water from the reservoir flows by gravity into the collector. Heated water rises through the channels and flows back into the tank. Thus, a natural circulation is created in a closed system.

The collector is made of a sheet of polycarbonate or other plastic with hollow squares inside, running along. To increase the absorption of sunlight and increase collector productivity (water heating rate), the plastic can be painted black. But here it is important to remember that the sheet is made of rather thin polycarbonate, therefore, with strong heating in the absence of circulation, it can soften or deform, which will lead to water leakage.

It is also worth noting that this device is not suitable for installation in residential premises for the purpose of hot water supply. This pilot project is more suitable for equipping a summer shower in a summer cottage.

Tools and materials

From the tools you will need:

- Circular and hand saw.

- Electric drill.

- Knife.

- Roulette.

- Screwdriver.

- Gun for silicone glue.

- Construction stapler.

Collector Materials:

- Polycarbonate sheet with hollow channels.

- The tube is made of ABS plastic.

- 4 caps on the tube.

- 2 ½ inch threaded plastic nipples with hose fitting.

- Tube of silicone sealant.

- Spray can if painting is planned.

Materials for the frame:

- 1 sheet of plywood.

- Styrofoam sheet. You can also use foam squares.

- Wooden beam with a section of 100 × 100 mm.

- Plastic film, adhesive tape.

- Bolts, nuts, washers, brackets for fastening.

Materials for organizing water circulation:

- A suitable tank or water tank.

- To connect the tank, you will need a garden hose, the length of which depends on the remoteness of the water tank from the collector itself.

- Several hose clamps.

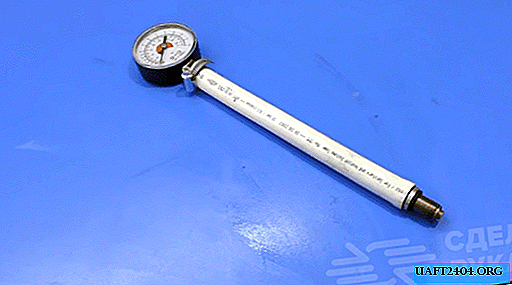

For clarity, testing the performance of the hot water collector, I used a digital thermometer.

Step-by-step solar collector assembly technology

First of all, you need to cut the polycarbonate sheet to the required dimensions. I planned to make a 1 × 2 meter collector, and proceeded from this fact. The sequence of work is as follows:

- A pipe made of ABS plastic is cut into pieces of such a length that it matches the width of the sheet. In my case, it is 1 meter.

- In the side of the two caps you need to drill holes for the nipples. If there is no drill of suitable diameter, you can expand the small hole with a round file.

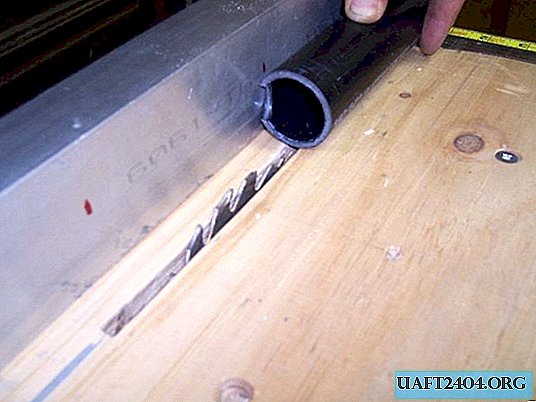

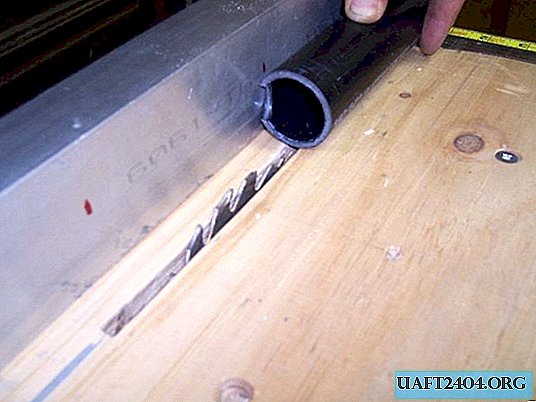

- To plugs with installed adapters put on pipes, they had to cut a semicircular hole, as shown in the photo.

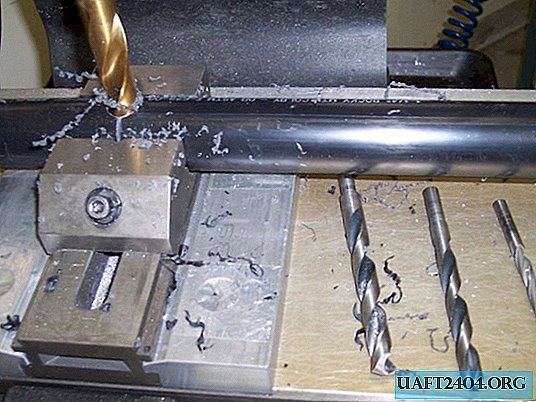

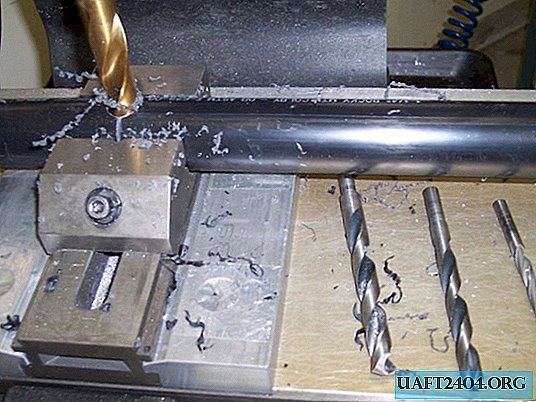

- Then, using a table saw, I cut both tubes so that I got a C-shaped section.

When performing this operation, you need to be careful and take into account the location and the necessary direction of the nipple adapters.

- The same cut must be made in the caps so that the plastic panel can enter them.

- When all the preparatory operations are completed, you need to collect all the parts dry to make sure they are compatible, and, if necessary, carry out fitting.

- When all elements are fitted, the structure is disassembled and reassembled using silicone glue to seal all joints. In addition to lubricating the joints with sealant, I recommend that after assembly, apply a little silicone on the outside of all joints.

In order for the sealant to dry well, the assembled structure must be left stationary for about a day, after which you can proceed to check for leaks. To do this, hoses are connected to the inlet and outlet adapters, one of which is connected to the water supply. After the collector is completely filled with water, all seams and joints are checked for leaks. If leakage is detected, the water drains and after drying, the problematic connection is resealed.

In order to be able to calculate the productivity and efficiency of the collector, you need to find out its volume. To do this, the water from the collector must be drained into a container. For example, my panel contains 7.2 liters (including hoses).

Frame manufacturing and panel assembly

In principle, the collector can already be used by laying it on a roof or other flat, fixed surface. But I decided to make a kind of case for the plastic panel in order to reduce the likelihood of damage when raising / lowering the shed from the roof, in which I decided to equip an outdoor shower, since I think of removing it for the winter.

The phased assembly of the housing is described below:

- The plywood sheet is cut to the size of the assembled collector with a 10 cm overlap on each side (previously I painted the plastic sheet black with spray paint).

- I drilled holes for the output of fittings for connecting hoses.

- I placed 50 mm thick polystyrene foam on the plywood.

- I laid the plastic collector on top of the polystyrene foam.

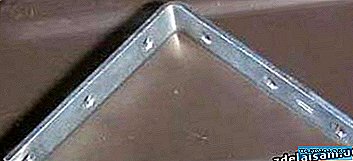

- From all sides of the panel, a wooden block was screwed to the plywood, which serves as a kind of fence.

- From above, the whole structure was covered with a dense plastic film, which was fixed with tape and brackets using a construction stapler.

Thus, I received a thermal collector in a reliable "case", thanks to which the plastic panel is protected from mechanical stress.

Note! I used ordinary transparent polyethylene, but in the photo it looks as if it is white - these are glare.

System filling

Now you can fill the collector with water and test the performance of the system. I installed it at an angle, and the tank (empty) is a little higher. One hose connects to the lower fitting, the second to the upper. To fill the system with water, I connected the bottom hose to the water supply and opened the valve a little so that the system gradually filled with water. This is necessary so that the water gradually displaces all the air. When water started flowing from the second hose (the collector was completely full), I opened the valve to the full so that the remaining air would come out under the pressure of the water. I also filled a water tank.

When air bubbles ceased to be observed in the flow of water leaving the outlet hose, I blocked the water and immersed both ends of the hose in the water in the tank (they should always be under water so that air does not enter the system).

Testing and testing a solar water heater

When the system is full, under the influence of solar heat, the water in the thin channels of the plastic panel heats up and gradually moves upward, forming a natural circulation. Cold water comes from the tank through the lower hose, and the heated in the collector enters the same tank through the upper hose. Gradually, the water in the tank heats up.

For clarity of the experiment, I used a digital thermometer with an external temperature sensor. First, I measured the temperature of the water in the tank - it was 23 ° C. Then I inserted the sensor into the outlet hose, through which heated water flows into the reservoir. The thermometer showed 50 ° C. The solar water heating system works!

Conclusion

According to the results of testing the performance of the collector system for 1 hour, I received heating of 20.2 liters of water (7.2 liters in the collector itself and I collected 13 liters in the tank for the experiment) from 23 to 37 ° C.

Of course, the performance and efficiency of the system depends on solar activity: the brighter the sun shines, the more water will heat up and a larger volume can be heated in less time. But for the summer soul, I think this collector is quite enough.

Original article in English

Share

Pin

Tweet

Send

Share

Send