Cheap cast iron clamps, which are full on the market today, do not differ in high quality, so they break even with a slight pressure. However, broken clamps can be repaired and even made much more resilient.

What to do and where to start?

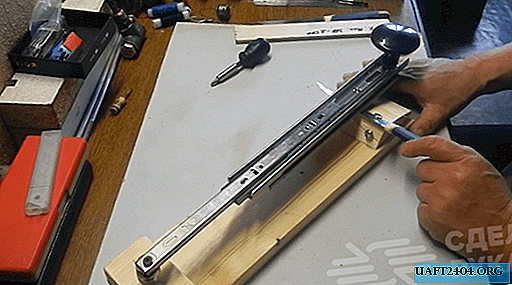

From a steel pipe with a diameter of 20 mm (3/4 inch), you need to cut a small sleeve into which you need to place a sleeve with an internal thread from a broken clamp, and then compress everything in a vice.

First, it is necessary to make a cut along the pipe segment with a grinder, so that it is easier to put a cast-iron sleeve from the clamp into it, and then everything is well-scalded.

Then you need to cut a short tube from a steel pipe 15 mm at an angle of 45 degrees (on both sides) and weld it to the resulting sleeve at one end.

After that, it is necessary to cut off two more tubes from a pipe with a diameter of 15 mm and weld everything into a single structure in the form of a clamp. A threaded pin can be used factory or can be made independently.

Practical application

Unlike cast iron, a clamp made of steel pipes will last much longer, and its scope is much wider. The detailed manufacturing process of such a reinforced clamp you can see in the video on our website.