Even an ordinary razor can be given an exclusive and original appearance, if desired, by making a beautiful wooden handle for it. The quality of the handle largely determines how comfortable the shave will be.

With the appropriate tool for wood processing, this process does not take much time. You will need a drilling machine, jigsaw, miter saw. Most of the work on manufacturing razor handles will take place on a lathe.

Preparatory work

First of all, you need to cut small rectangles from different types of wood (it is better to use light and dark wood), and then glue them with a "herringbone". Next, we grind the resulting workpiece, make a marking with a square and cut off the excess parts.

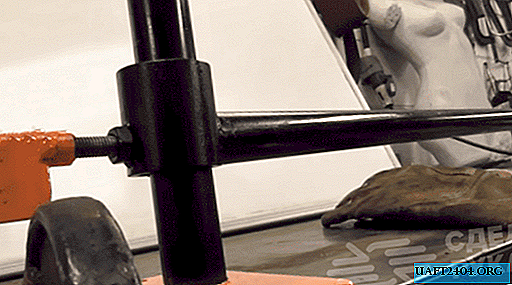

On a drilling machine, in the center of the bar, drill a hole of a suitable diameter, insert a metal tube into it, after which you can proceed to the next stage of work.

Mechanical restoration

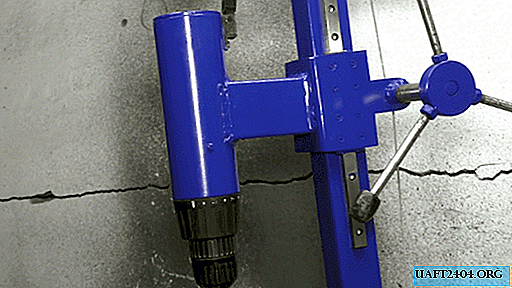

We fix the wooden workpiece in a lathe and process it, giving it the necessary shape. Mechanical processing of the product is the longest stage of work, however, it is here that patience and perseverance should be shown so that the final result meets expectations.

At the final stage of turning, the wooden razor handle must be sanded and then coated in several layers with colorless varnish. We insert a beautiful steel plug into the bottom of the handle, and a mount for the razor head into the top. The main stages of the work can be seen in the video on our website.