In a conventional bench vise, it is quite problematic to securely fix a round pipe (for example, to cut a thread). If you squeeze the jaws of the vice very hard, then the pipe may deform (especially thin-walled).

If, on the contrary, you do not squeeze the vise, then it will rotate around its axis and it will simply be impossible to work with it. You can, of course, drill a hole in the pipe to fasten it to the working surface and grab it with welding. However, such radical measures are not always advisable.

To fix a round pipe in a bench vise (if you don’t have a tube vise at hand), you can make a simple fixture from an old file and corner. With this homemade product you can tightly clamp pipes of different diameters.

How to make a fixture for fixing pipes

From the old flat file, we cut off the grinder with three identical segments of 7 cm each, after which we impose them one on top of the other and grab them by welding. We clamp the workpieces in a vice and cut a triangular wedge in the center. Then with the help of angle grinders we make "steps".

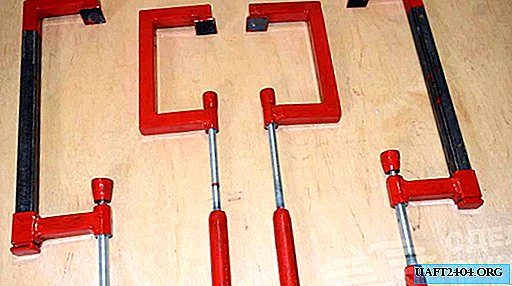

After that, we disconnect the workpieces and weld them to two corners. We cut off the excess protruding parts by the grinder and grind the surface of the parts. We install home-made clamps from a file in a bench vise, between them we put a round pipe, after which we clamp the jaws.

That's how simple it is to make at home a practical fixture for fixing steel round pipes of different diameters in a bench vise. The main stages of work, see the video on our website.