This homemade machine has a fairly compact size, and therefore does not take up much space in the workshop. Moreover, the device itself is versatile in use - due to the presence of a special adapter for mounting disks from the grinder, all disks and brushes can be installed on a home-made grinding machine.

As a drive, a power electric drill is used, which is mounted on a movable metal platform. The base itself is made of profile pipes and is attached to the working surface of the table. Even for the manufacture of a horizontal grinding machine, pieces of steel strip of different lengths and bolts with nuts will be required.

Design features of a grinder from a network drill

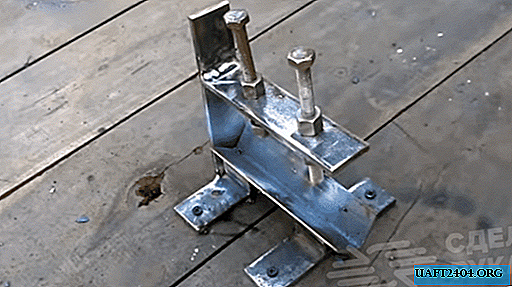

The first step is to cut the blanks for the base of the structure - the mobile platform. In two steel strips of the same length, holes are drilled at the edges, after which they are interconnected using transverse plates by electric welding. The result should be a rectangular frame with "ears" for attaching to a table or other surface.

From a piece of steel pipe of suitable diameter, two nuts and a bolt, a clamp is made on a drill, which is worn on the "neck" of the body. A segment of a square section profile is welded in the center of the strip, and a clamp is attached to it. After that, the frame of the movable part of the structure is welded from profile pipes of various lengths.

From a piece of a metal plate and two short sections of a strip, a working table is made for processing parts and blanks. The surface of the movable platform is cleaned with a grinder so that it can be painted. Then, a drill with an adapter and a disk is installed in the "landing socket" of the structure, after which you can begin to work.