Have you ever had a situation where you need to drill a hole in a critical part? They grabbed the drill with his hands, stepped on the board with his foot, everything moves, plays, the intended place moves. At such moments, a drilling machine would come in handy. The thing is necessary, but expensive - not everyone can afford it.

It is enough for a masterful master to see how easy it is to make this device from auxiliary materials, and to realize this idea. Moreover, no difficulties are expected in the manufacture of a drilling machine.

And you don’t have to buy materials - for this purpose unnecessary rubbish is quite suitable, which almost always can be found in a garage or a home workshop.

To implement this idea, several oak beams, furniture guides, clamps, a gear from a screwdriver and an engine are suitable. The master uses everything at hand. Nothing was acquired in advance. All the details were gathering dust in the workshop, finally, they find the right application.

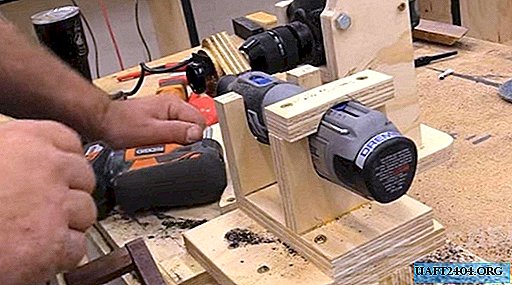

The manufacturing process of a simple drilling machine

Furniture rails are mounted on prepared bars. Two pieces of wood from a length of 10 cm are glued together - you get a movable part into which the clamps are screwed. There, the master inserts the gear from the screwdriver, and centers.

A handle is made from a square profile pipe for lowering the cartridge with the engine when drilling the workpiece. It turned out a convenient, useful thing. Now, if you need to make several even holes, there will be no problems.

Of course, it will be difficult to drill thick corners of metal, but such an assembly was not conceived for this. Make a dozen holes in a long board or urgently repair the cover of an old cabinet - there is enough power for such needs with a margin.