Bench vice is available in almost every home workshop and garage - they greatly facilitate the processing of metal blanks. However, it is not very convenient to clamp round pipes in them. To fix this, you can make homemade clamping jaws for them.

They not only allow rigid fixation of steel round pipes, but also profile pipes when it is necessary to install them with the edge up. You can make such sponges from improvised materials.

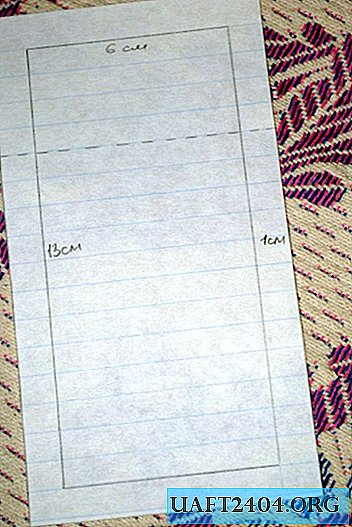

The first step is to cut off two pieces of a building corner 8 cm long (along the length of the lips of a bench vise). Also, along the length of the cut corners, four more pieces of the round pipe will need to be cut.

The main stages of work

For each segment (to one of the shelves) of the corner, it will be necessary to weld two segments of a round pipe. Previously, the surface of the workpieces must be cleaned from corrosion, if any. After welding, grind the seams with a grinder.

Next, you need to cut off two pieces of a metal square. They must be welded to the second shelf of the corners. It is also advisable to immediately clean welds with an angle grinder.

Self-made clamping jaws are simply installed on the jaws of a vice, and between them the workpiece itself is clamped - a round or profile pipe that needs to be processed. A detailed process for making homemade products, see this video.