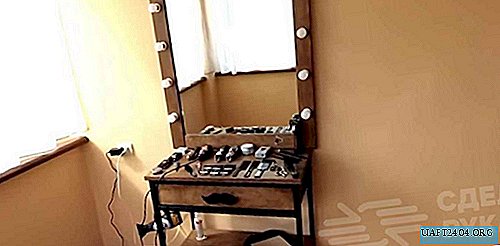

As the basis for the manufacture of a home-made grinder for the workshop and garage, the author decided to use a polishing machine. This is very convenient, since it allows you to adjust the speed of rotation of the motor shaft - from 600 to 3000 rpm.

The first step is to remove the disc from the polisher. Instead, a homemade device will be installed.

First you need an elongated nut M14, as well as a piece of steel pipe of suitable diameter - about 60 mm long. The nut is inserted into the pipe and then scalded.

The weld will need to be cleaned with a grinder with a petal circle. The resulting roller is mounted on the shaft of the polishing machine.

The main stages of work

Then in the profile pipe 20 * 20 mm and a length of 300 mm, the master drills two holes of 8 mm. Between them, with the help of a grinder, you need to cut through the "window".

Then, in the section of the profile pipe, the master drills two more holes. The same holes will need to be drilled in a protective casing from the grinder. Then both parts are joined together.

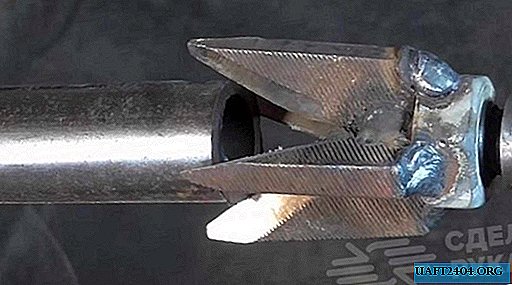

The next step is to screw a threaded rod into the roller. We put a puck on top, cut off the excess, and clean it.

For the tensioner you will need a piece of metal corner. We drill two holes of 8 mm in it. Then the corner is screwed to the profile pipe.

Next, take a suitable bolt in size, put on two bushings and fix on the corner. The result was a tensioner pulley. The master sets the sanding belt in place and sets the corresponding position of the roller.

For more information on how to make a simple home-made grinder from a polishing machine, see the video on the website.