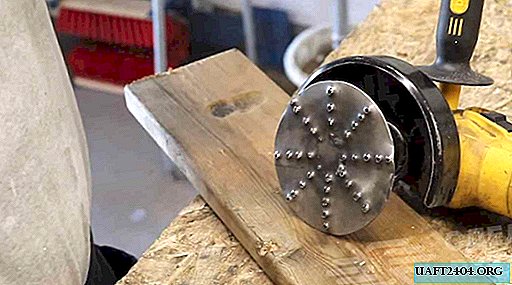

In this review, the author makes a do-it-yourself homemade nozzle on the grinder (angle grinder) for processing wood blanks.

By the principle of operation, the nozzle is somewhat reminiscent of an grinding wheel, but it is hardly possible to call this process grinding. More likely - peeling.

It should also be noted that the nozzle, although working (at least in the video it looks that way), is rather unsafe.

If you make a choice between this homemade nozzle and factory disks for angle grinders, then it is better to give preference to the latter. They at least pass some tests.

The main stages of work

First of all, the author cuts out a circle of the desired diameter from a piece of sheet metal (depends on the size of the grinder).

After that, the author makes markings on the workpiece and punches holes.

The next step will require a sleeve and nut. The sleeve can be made from a piece of pipe. The author welds the parts together, cleans the welds.

Then the sleeve with the nut will need to be welded in the center of the hole disc.

With the help of such an abrasive-grinding nozzle, the author processes the surface of boards, OSB, plywood.

Details on how to make a homemade nozzle for processing wood blanks can be seen in this video.