Share

Pin

Tweet

Send

Share

Send

The main materials:

- compressor from the refrigerator;

- 2 tees with a female thread;

- 2 fittings per hose;

- barrel;

- pressure gauge with an adapter for the diameter of the tees;

- crane;

- plywood;

- hose;

- fumlent;

- clamps.

When assembling the pump, 1/4 or 3/8 inch thread accessories can be used. It also requires a few trim pieces, bolts and nuts.

Conversion of the compressor into a vacuum pump

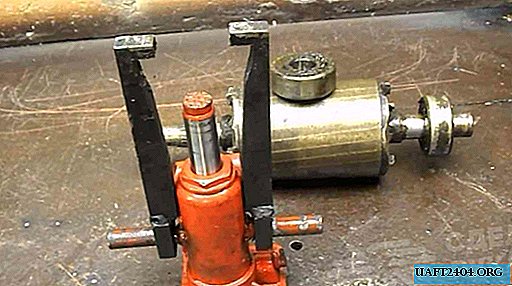

We cut off the compressor tubes, leaving them 3-5 cm long.

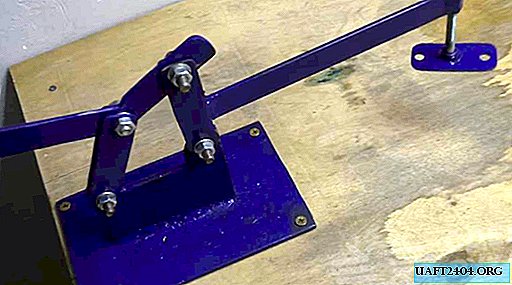

A plywood cut-out platform for the location of the compressor.

It can be varnished to protect against dirt and moisture.

To carry the pump, it is worth welding the handle in the form of a frame. Its base is made from corners, and the racks and the crossbar from any available metal. Corners are drilled and screwed to the bottom plywood.

The compressor is also fixed on the base.

At the next stage of assembly, you need to connect the tees with each other using a barrel. Before this, the threads are sealed with fumlent. A pressure gauge is twisted into one of the vertical outlets of the tees through an adapter. A crane is installed at an adjacent exit.

To fix the tees on a plywood base, you need to mount. For this, 2 rings are cut out of the pipe to which the studs are welded. In the rings, a hole is made for tightening the screws. The result is clamps acting on the principle of a clamp. They are screwed into plywood, and tees are already fixed in them.

Next, fittings are installed on the lateral open exits of the tees. One of them is connected by a hose to the air intake of the compressor. The connection is sealed with clamps.

A hose with a suitable adapter is installed on the second fitting to solve the required task.

If, for example, it is required to make stabilization of wood with a polymer, then the tube must be fixed on the metal lid of the can with an inserted fitting.

Then the polymer is poured into the jar, the tool with the wooden handle is laid and it closes. After switching on, the pump will draw air from the tank, and the composition will penetrate into the empty pores of the tree. Before turning off the compressor, slowly open the tap to release the vacuum.

Share

Pin

Tweet

Send

Share

Send