Share

Pin

Tweet

Send

Share

Send

Tools for removing the clip:

- a whole bearing of the same size;

- elongated pliers with curved jaws;

- screwdriver;

- head or tube;

- hammer

- grease for bearings.

Knocking out clips

A jammed clip does not have a hard surface that can be hit, so you need to put an inner ring and balls into it. They can be removed from an old seized or broken bearing.

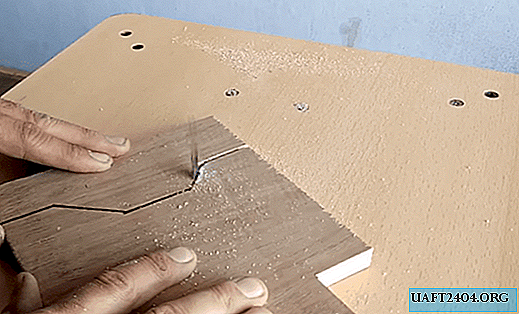

A similarly sized bearing is disassembled.

From it sidewalls break down.

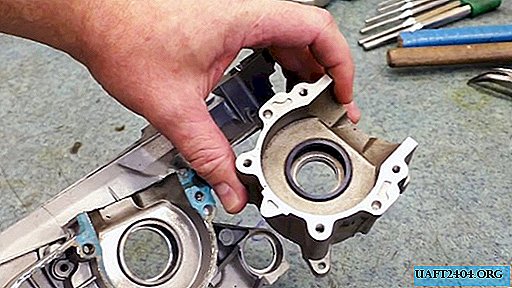

Next, you need to remove the separator.

If it is plastic, it is simply pry off with a screwdriver and removed. If there is a steel separator, it must be knocked out by punches between the balls. After breaking, he breaks out with pliers.

The separator itself is no longer needed, so you can not stand on ceremony with it.

Having released the separator, you need to move all the balls to one side to get a clearance.

Further, the inner ring is captured by elongated pliers and is turned to the lumen.

After displacement, the balls drop out of the bearing and the ring is removed from the upper cage. It’s easy, you can handle it without a vise.

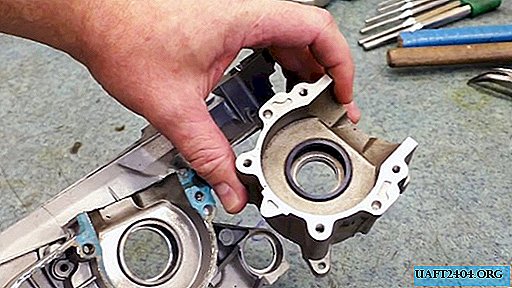

Now you need to put the extracted parts on a jammed clip in the housing. To do this, a thick lubricant is applied around its circumference.

Balls are glued onto it, laying on one side.

After their installation, the inner ring is started.

Next, you need to separate the balls, distributing them evenly. They can wedge, so you may need to use a screwdriver.

After assembling the bearing, it can be knocked out in the usual way. Before that, it is worth warming up the case with a hairdryer.

From heating, it will expand, increasing the bore diameter, which facilitates knocking out. A head is applied to the reverse side of the bearing and several hammer blows are applied to it. You can also use a puller.

This method of course will make you tinker a bit, but it is many times easier than trying to weld to the clip. No need to cut or drill anything, risking harm to the housing in which the clip sits.

Share

Pin

Tweet

Send

Share

Send