Share

Pin

Tweet

Send

Share

Send

Will need

- Steel circle 10 mm thick minimum and 200 mm in diameter.

- Steel strip 40 mm wide.

- Epoxy resin

- Eye bolt with nut.

- Well, of course, three microwaves.

Making a powerful electromagnet for a do-it-yourself crane

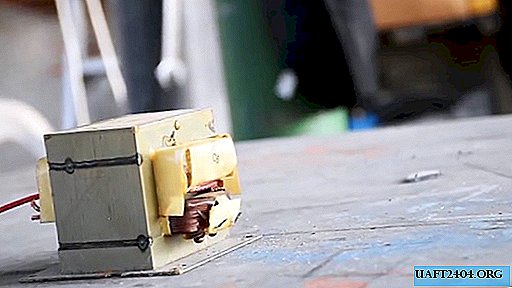

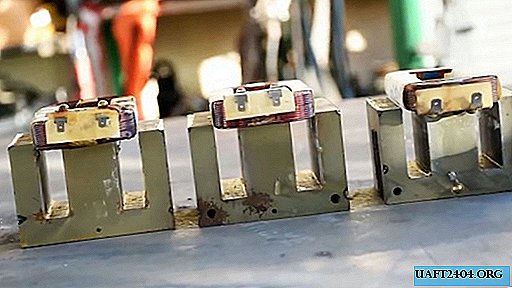

It is necessary to disassemble all the microwaves and pull out 3 transformers, respectively.

The transformer consists of a "Ш" -shaped magnetic circuit welded to an "I" -shaped magnetic circuit.

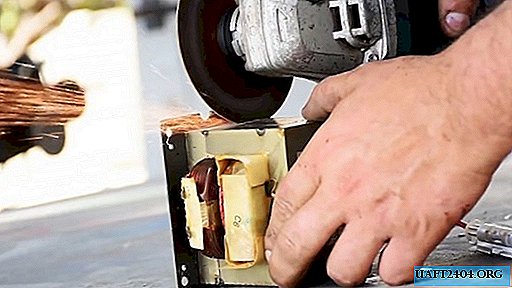

Grinder cut the seams at each transformer. We no longer need an “I” -shaped magnetic circuit.

We remove all the windings. There are usually three of them: network 220 V, low voltage 6 V and high voltage 2500 V. We leave only the network.

It was necessary to remove them all, because the network winding is the first, and the rest are already following it and there is no other way to get close to them.

We press the winding back to 220 V back. We put the transformers in a circle and check that they all fit and do not protrude.

In a steel circle, we drill two holes: one under the power wire on the side, the second precisely in the center for mounting.

We make the body of an electromagnet. From a steel strip on a bending machine, we make a circle along the diameter of the base.

We weld it to the base.

Insert the eyebolt into the central hole.

Fix on the other hand with a nut and weld everything by welding.

We install transformer cores with windings. Please note that the cores protrude beyond the main body magnet ring. The winding is well hidden behind the ring.

We weld the cores to the base.

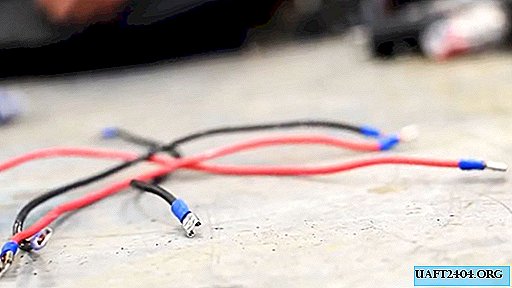

Putting the circuit together. We connect all the windings in parallel to each other.

We connect the power outlet.

Fill the empty area with previously diluted epoxy. For strength, a filler is introduced into it - dry cement.

We are waiting for complete solidification.

The sticking rectangles of the electromagnet are cut off by a reciprocating electric saw.

For evenness, we mill.

The electromagnet is almost ready.

It remains only to paint and proceed to the tests.

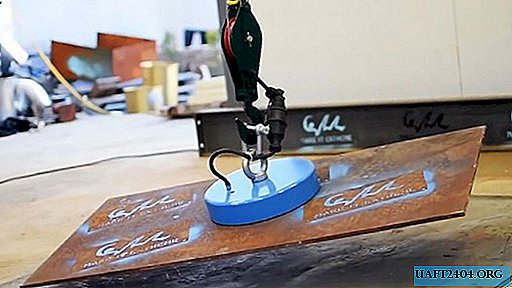

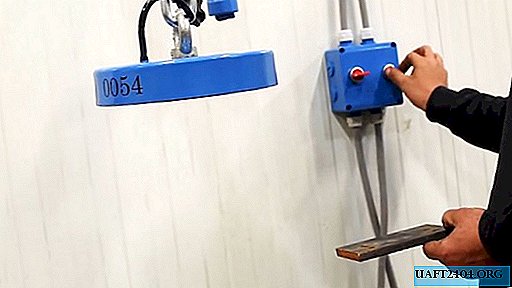

Result and tests of the electromagnet

The calculated electric power was about 2.7 kW. This is a good value, since the network of any workshop is able to withstand such loads. Turn on and check.

Holds up great.

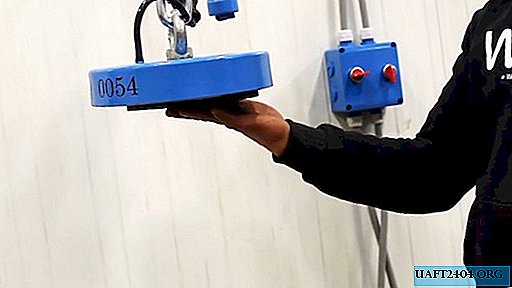

Now a steel sheet weighing 25 kg.

And to this load two more people with a total mass of 170 kg.

Total holds 200 kg quite confidently, maybe more.

Easily lifts a wide I-beam weighing about 80 kg.

In general, for a forge, workshop, a thing is just great to do everything quickly and easily. Now you don’t need to fix anything, just turn on the electromagnet and move the heavy part where you need it.

Share

Pin

Tweet

Send

Share

Send