Share

Pin

Tweet

Send

Share

Send

The need to cut the internal thread in the holes of wooden parts may arise when performing various types of work, for example:

- when assembling furniture;

- during the construction of shelves or supports in the utility rooms or garage;

- when assembling structures requiring the connection of wooden elements between themselves or with metal parts.

If you do not have the opportunity or desire to purchase the necessary tap for this in the store, I suggest making this tool with your own hands from an unnecessary bolt. You will spend no more than 5 minutes on this work and will be very pleased with the result.

Necessary tools and materials

We will need:

- angle grinder (grinder);

- clamp or vise;

- grinding machine (emery) with fine-grained stone;

- drill;

- a bolt or screw of the required length with a thread of the desired size.

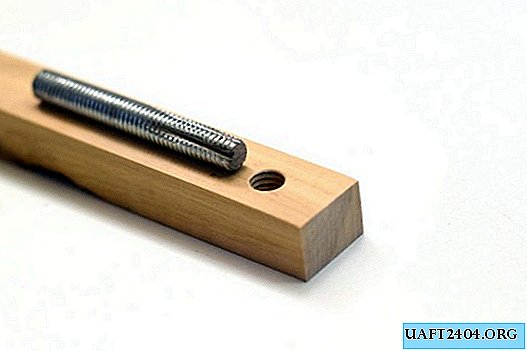

Giving the future tap the necessary shape

If you use a bolt or screw, cut off his turnkey head or screwdriver. If you find, you can immediately take the threaded rod of the desired size. This will allow the future use of a tap with a drill or screwdriver.

Next, you need to create a small cone at one end of the thread. I did this on a desktop emery machine. During grinding, the bolt must be constantly rotated to ensure uniform taper.

For this, I recommend clamping our headless bolt (or stud) into the drill chuck and turning it by turning the drill on at low speed. In this case, the bolt must be oriented relative to the plane of the grindstone at a small angle, providing the desired taper. In this way, we get a centered, regular-shaped cone of our tap.

When performing this phase of work, the threads of the thread should not be completely drained even in the initial part of the tap.

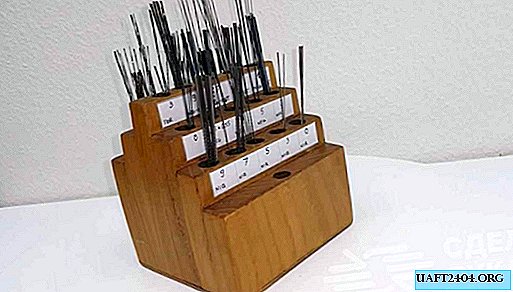

Cut the grooves on the tap

We fix the tap with a clamp or clamp it in a vice. Using a grinder, we perform 3 or 4 longitudinal slots located evenly around the circumference of the tap.

Cut grooves will allow you to remove sawdust during threading, and the sharp edges of the threaded threads formed by the grooves will easily cut into the tree.

Clean tap thread

Take the nut with the corresponding thread and, having screwed it onto the tap, drive it several times along the thread in the forward and reverse direction. As a result, small burrs will be removed that will inevitably occur when grooving longitudinal grooves.

Now you can clamp the tap into the drill chuck and make sure that it works correctly. If you are afraid that the drill chuck will be scratched by the thread of the inoperative part of the tap, grind it on the emery. I did not do this and did not notice the damage to the cartridge. In fact, bolts are usually made of milder steel than a drill chuck.

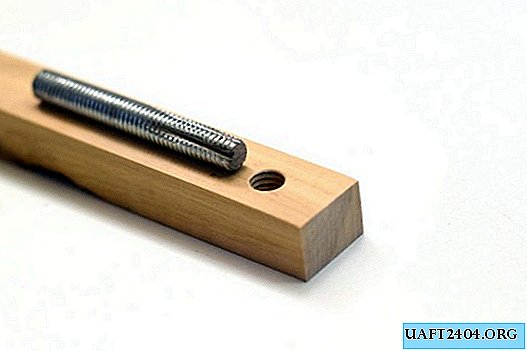

We make a thread

Drill a hole in the tree whose diameter is slightly smaller than the internal diameter of the tap thread.

When threading, move slowly, after 1 - 2 turns of the tool, turn on the reverse and, pulling out the tap, clean it of chips. This will allow threading without flaws.

Keep in mind that the thread carved in wood is not as strong as metal, but in some designs its strength is quite enough.

Original article in English

Share

Pin

Tweet

Send

Share

Send