Share

Pin

Tweet

Send

Share

Send

Miniature welding of metal conductors or small parts can be done with a simple pencil stick. A mini welding machine with a graphite rod can not only weld, but cut metals of small thickness.

How to apply it and for what, I think, you decide.

Will need

- A step-down transformer.

- A simple pencil.

- Wires.

- Clamp, such as a crocodile.

Training

For a miniature welding machine, you need a transformer with an output voltage of 27 V. Its power is somewhere around 50-60 watts. You can take any other transformer with similar characteristics, or use ready-made sources with adjustable voltage.

The pencil is simple. It must be carefully cut by gluing, without damaging the inner core.

We make improvised terminals. Crocodile for a common wire, and a homemade wire hook for an electrode.

We fix the graphite rod in the holder. Solder the wires to the transformer.

Metal welding

Before you start welding anything, take care of safety precautions. Be sure to use safety glasses and do not touch live parts. All actions you do only at your own peril and risk, so be careful and careful.

For welding, prepare a refractory surface: brick, piece of stone or tile, etc.

Getting down. We will weld two copper wires. We connect the common one to the wires being welded, and we touch the surface to be welded with the electrode.

Initially, the arc does not ignite, the stylus smokes. For an initial launch, this is normal.

After a couple of seconds, the rod warms up enough and voltage with temperature is enough to ignite the arc.

We continue welding. The main thing here is not to burn the rod, as it heats up to redness and breaks. Therefore, periodically remove it by breaking the arc to allow it to cool slightly.

As a result, copper conductors are perfectly welded.

They can’t be broken, since the knot has become one.

Such a useful property in the economy will definitely be found where to apply.

Metal cutting

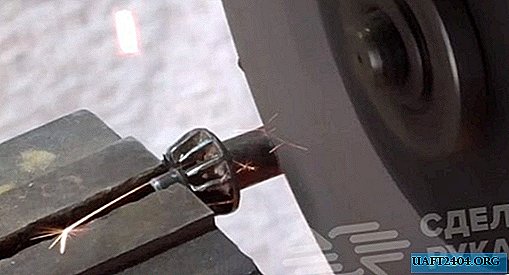

As with a real welder, this mini model also knows how to not only weld, but also cut metal.

But for this it will be necessary to increase both the temperature and the current. This can be achieved by reducing the length of the electrode.

As a result, the temperature rises sharply. Cut off the screw.

Of course, I had to spend a little more time, but everything was cut well.

A big plus of such a craft is that no expensive materials are used, but five minutes is enough to collect everything.

Do not underestimate the advantages of such a device, in some cases it can definitely come in handy.

Watch a more detailed video.

Share

Pin

Tweet

Send

Share

Send