Share

Pin

Tweet

Send

Share

Send

Most likely it was abrasive blasting, extremely popular in the past. Due to the aggressive effect on the base, the impossibility of using it for new composite, polymer materials and plastics, as well as damage to health, this method has lost its former popularity.

And if at the enterprises today sandblast cleaning with quartz sand has almost been abandoned, then in the household it can provide invaluable assistance. Ask which one? Let's sort it out in order.

What is home sandblasting used for?

This installation can hardly claim to be a professional tool. But in a private house or courtyard, where repairs never end, such an assembly is very useful. Well, if you need to clean the old metal tank from rust, repaint the old fence or doors and windows, with our sandblasting such work will be only a joy.

You can make sandblasting at home practically from improvised materials, spending a minimum of time and money. For this we need the following materials:

- Compressor;

- Air gun for blowing off dust;

- Plastic bottle with cap (PET);

Of the tools: a screwdriver, a drill of the desired diameter, a vernier caliper and a file.

Do not forget about safety, because sand can get into the eyes or respiratory tract. In working with home sandblasting, it is best to use tight overalls, safety glasses, a respirator and gloves. Work shoes will also not be superfluous. It is also necessary to keep the compressor itself at a distance, because sand that has turned into dust can clog its air filter and overheat the engine.

Getting started making sandblasting

First of all, it is necessary to prepare a pneumatic gun, or rather its spray nozzle. Before removing it from the gun, be sure to mark the area of the sand feed hole. It should be located approximately in the middle.

We twist the sting nozzle with a tube at the end. The tube for such pistols is usually about 6-10 cm long. We will work with it.

Clamp the replacement nozzle in a vice and grind one of the walls of the tube. Since it is made of soft metal, it is most convenient to do this with an ordinary flat or tetrahedral file. The hole should be no more than 1 cm wide. The fewer burrs remain on the walls of the machined hole, the freer the sand will pass through it into the nozzle of the gun.

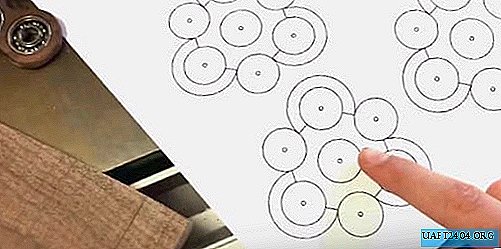

We measure the diameter of the tube with a caliper and select a drill for it. It is necessary to calculate its diameter in such a way that the gun tube fits very tightly into the neck of the bottle.

Now you need to drill the base of the bottle at the very neck. We use a screwdriver for this work, and drill through the PET.

We twist the nozzle back into the gun, and fill the bottle with sand. It can be prepared using a sieve, calculating the size of the fraction for a certain type of work and base.

Insert the tube of the gun into the hole made in the sand bottle. It should be noted that during operation the sandblasting bottle should remain in a vertically inverted position.

All that remains is to connect the compressor to the air gun and try our sandblast in action!

Watch the sandblasting video

media = // www.youtube.com/watch?v=nzmG4njeyRY

Share

Pin

Tweet

Send

Share

Send